In the ever-evolving landscape of the juvenile products industry, identifying reliable baby product manufacturers and suppliers is the cornerstone of business success and consumer safety. As parents increasingly prioritize durability, non-toxic materials, and ergonomic design, the burden falls on manufacturers to innovate. Among the rising stars in the Southeast Asian manufacturing hub, AUTORU has established itself as a formidable entity. This comprehensive guide explores the intricate manufacturing ecosystem of AUTORU, detailing their production capabilities – from automatic baby cradles to solid wood furniture – and analyzing why they are becoming a preferred OEM partner for global brands.

Autoru baby products manufacturer

When discussing top-tier baby product manufacturers, longevity and specialized expertise are the key indicators of quality. AUTORU has carved a unique niche in this sector by blending traditional childcare methods with modern technology. Over the past two decades, I have seen a shift in the market where “Made in Vietnam” is increasingly synonymous with high-quality craftsmanship and competitive pricing, and AUTORU is at the forefront of this movement.

As a manufacturer, AUTORU is not just an assembly line; it is a full-cycle production house. Their reputation is built on understanding the physiological needs of infants—specifically the need for rhythmic motion to induce sleep—and translating that into mechanical engineering. Unlike generic suppliers that simply re-label imported goods, AUTORU designs, engineers, and fabricates their core products in-house. This vertical integration allows for strict quality control, ensuring that every screw, motor, and fabric stitch meets international safety standards. For retailers and distributors, partnering with a manufacturer like AUTORU means accessing a supply chain that values consistency, safety, and innovation.

Introduction to the Autoru manufacturing

To truly appreciate the quality of a product, one must understand the facility where it is born. The AUTORU manufacturing plant is a testament to modern industrial efficiency tailored specifically for the delicate nature of baby products.

The manufacturing process at AUTORU is divided into several specialized zones, each dedicated to a specific aspect of production:

- Metalworking and Frame Fabrication: The skeleton of any baby swing or cradle must be robust. AUTORU utilizes high-grade steel and aluminum processing units where tubing is cut, bent, and welded with precision. The structural integrity of their hammock stands and cradle frames is tested to withstand weights far exceeding the average toddler, ensuring a significant safety margin.

- Painting Workshop: AUTORU’s painting facility is equipped with an advanced automatic coating system that ensures an even, consistent finish across every surface. A closed spray booth minimizes dust and contaminants, while a controlled heat-drying line regulates time and temperature to achieve optimal paint adhesion and durability. This process not only enhances the smoothness and appearance of the product but also improves scratch resistance and protects metal frames from environmental impact.

- Plastic Molding Workshop: AUTORU also manufactures its own plastic components using high-quality virgin plastic pellets. These materials are processed through advanced injection molding machines, applying precise molding techniques to produce sturdy, durable, and dimensionally stable plastic parts. Strict quality control—from raw materials to finished components—ensures that every plastic piece meets safety standards for children and maintains long-lasting durability in AUTORU’s baby swings, cradles, and childcare equipment.

- Woodworking and Finishing: For their wooden furniture lines, the facility employs advanced CNC machinery alongside skilled carpenters. This ensures that every crib and high chair is free from splinters and sharp edges. The finishing process uses non-toxic, lead-free paints and varnishes, strictly adhering to safety regulations required for products that babies might teethe on.

- Textile and Assembly: The final stage involves the sewing of breathable, hypoallergenic fabrics and the final assembly of the units. Here, quality assurance teams inspect the stitching, harness strength, and overall finish before packaging.

This holistic approach to manufacturing allows AUTORU to maintain high output capacities while remaining agile enough to adapt to new market trends, such as the growing demand for portable and space-saving baby gear.

What baby products does the AUTORU manufacturing plant produce?

The diversity of a manufacturer’s portfolio is often the deciding factor for international buyers and local distributors. AUTORU manufacturing plant distinguishes itself through a versatile production capability that spans metal fabrication, electronic assembly, and advanced woodworking. Unlike niche factories that produce a single type of item, AUTORU operates as a comprehensive solution provider for the nursery sector.

From my perspective as an industry analyst, this diversification is strategic. It allows retailers to source a complete nursery setup—from sleep solutions to feeding gear—from a single, reliable supplier. This section details the specific manufacturing protocols and product lines that define the AUTORU brand.

Manufacturing baby cribs

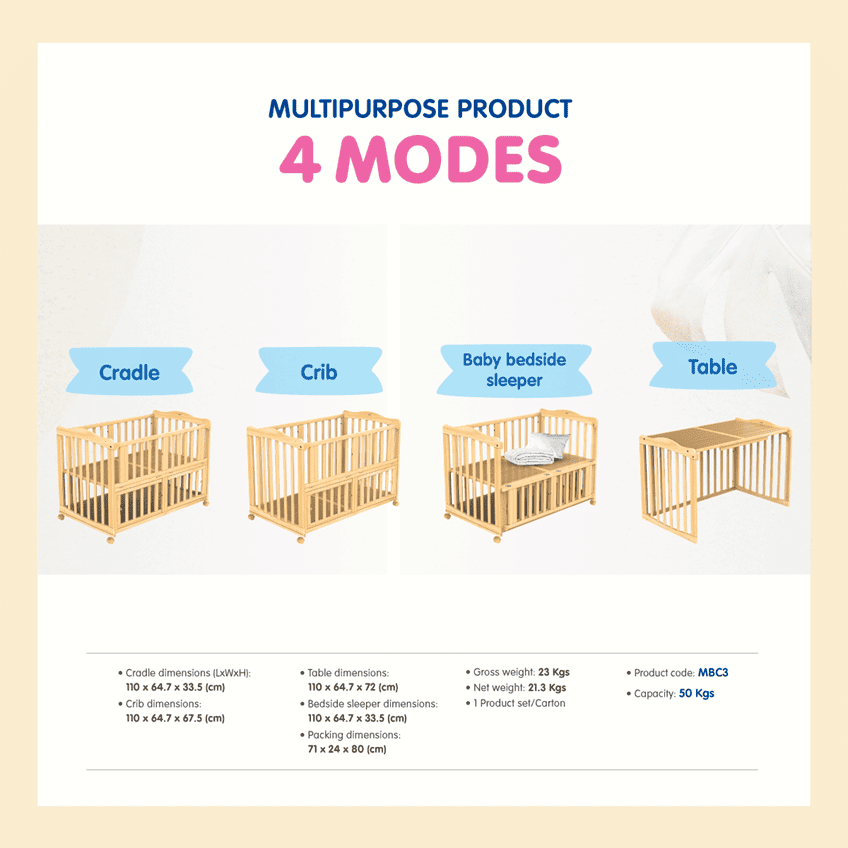

The production of baby cribs is perhaps the most scrutinized area in the juvenile products industry due to strict safety regulations regarding slat spacing, corner post heights, and structural stability. At AUTORU, manufacturing baby cribs begins with the careful selection of timber. The factory predominantly utilizes high-quality solid wood, often New Zealand pine, known for its density and resistance to warping.

The manufacturing process involves precision cutting and sanding. Every slat is measured to ensure the gap does not exceed standard safety recommendations (typically 2-3/8 inches) to prevent infant entrapment. The joinery uses heavy-duty hardware that is concealed or recessed to prevent snagging on a child’s clothing. Furthermore, the finishing line applies multiple coats of non-toxic, water-based stains that are free from lead and phthalates. This ensures that when a teething baby chews on the rail—a common occurrence—they are not ingesting harmful chemicals. The result is a crib that is not only aesthetically pleasing but engineered for longevity and absolute safety.

Manufacturing automatic baby cradle

This is the flagship domain where AUTORU truly excels. Manufacturing automatic baby cradles requires a fusion of mechanical engineering and ergonomic design. The core of this product is the proprietary motor mechanism, which is designed and assembled in-house to ensure a smooth, noise-free operation.

The production line focuses on the calibration of the rocking speed. Unlike standard swings, an AUTORU automatic cradle is calibrated to mimic the frequency of a human heartbeat or a mother’s swaying motion. The frame construction usually involves reinforced steel tubing, powder-coated to resist rust and scratching. A critical aspect of this manufacturing process is the electrical safety testing. Every power adapter and motor unit undergoes rigorous stress testing to prevent overheating, ensuring the cradle can operate safely for extended periods. This attention to the “automatic” component places AUTORU ahead of competitors who rely on manual rocking mechanisms.

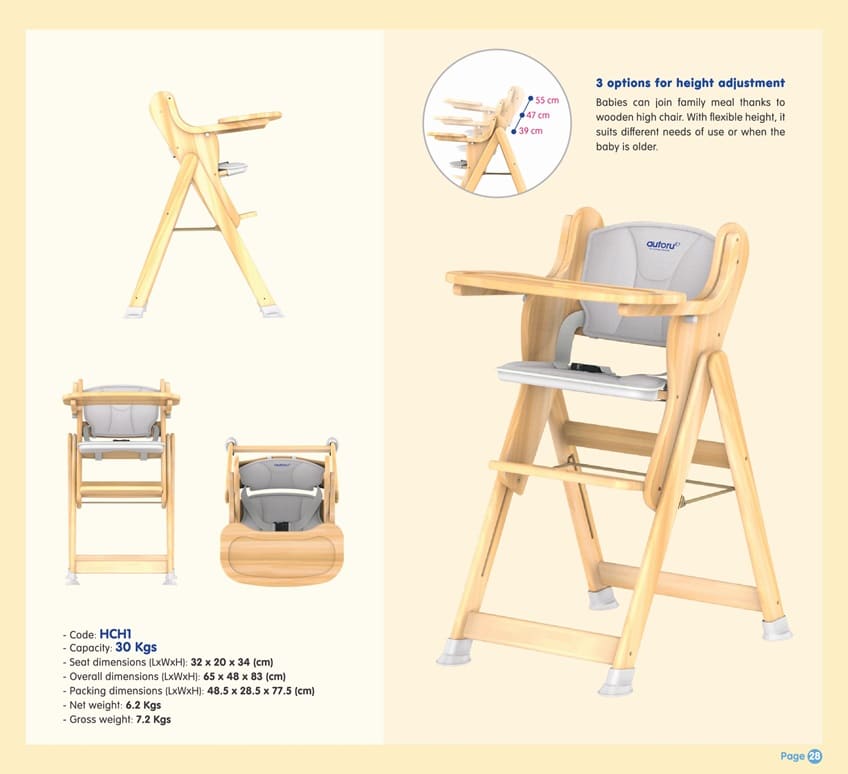

Manufacturing baby high chairs

When manufacturing baby high chairs, stability is the primary objective. AUTORU produces high chairs that are designed to prevent tipping, even when a child is active or restless. The engineering team focuses on a wide-base design, utilizing solid wood or reinforced metal legs to create a low center of gravity.

The production process includes the fabrication of adjustable components. Modern parents demand versatility, so AUTORU manufactures chairs with multiple height adjustments and recline positions. The trays are molded from food-grade, BPA-free plastics that are dishwasher safe and resistant to staining. From a textile perspective, the seat pads are sewn from easy-to-clean, water-resistant fabrics. The integration of a 5-point safety harness system is a standard step in the assembly line, anchored directly into the frame to withstand sudden movements.

Manufacturing baby bouncers and rockers

Manufacturing baby bouncers and rockers at AUTORU is centered on portability and ergonomics. These products are designed to be lightweight yet sturdy. The frames are typically bent from high-tensile alloy tubes that offer a natural “bounce” without the need for mechanics, reacting to the baby’s own movements.

The sewing department plays a crucial role here, creating mesh or padded seats that support the infant’s spine and head. Specialized attention is given to the incline angle; during my 20 years in the industry, I have noted that the correct angle is vital for preventing reflux in infants. AUTORU engineers ensure the recline is optimized for both play and rest. The final assembly includes non-slip rubber feet, a small but essential detail that prevents the bouncer from sliding on smooth floors like tile or hardwood.

Manufacturing Portable Hammock Stands

In many Asian cultures, and increasingly in Western markets, the hammock is a revered sleep aid. AUTORU’s division for manufacturing Portable Hammock Stands focuses on heavy-duty industrial design scaled for home use.

The steel used here is of a thicker gauge than standard baby gear. The manufacturing process involves cold-rolling steel and applying electrostatic powder coating technology. This ensures the stand is resistant to environmental factors like humidity. The key innovation is the folding mechanism. The joints are engineered with high-tolerance bearings to allow the stand to fold compactly for travel or storage without compromising structural rigidity when expanded. Load-bearing tests are conducted to ensure these stands can support not just a baby, but often the weight of an adult, demonstrating superior durability.

Manufacturing wooden furniture

Beyond specific baby gear, AUTORU has a robust capacity for manufacturing wooden furniture. This broader category includes changing tables, wardrobes, and storage units for the nursery.

The woodworking facility operates with sustainable practices, ensuring high material efficiency. The production utilizes advanced joinery techniques like mortise and tenon for superior strength compared to simple nail-and-glue construction. The focus here is on smooth edges and rounded corners—a mandatory safety feature in any child-friendly environment. By controlling the entire wood processing line, from raw timber drying to final lacquering, AUTORU ensures consistent color matching across different furniture pieces, a key selling point for retailers offering nursery sets.

Manufacturing home furniture

Leveraging their expertise in wood and metal, AUTORU has expanded into manufacturing home furniture that complements their juvenile lines. This includes items that can transition from nursery use to general home use, such as rocking chairs for nursing mothers or modular storage shelves.

This manufacturing line emphasizes durability and aesthetic versatility. The design philosophy adheres to minimalist and functional styles, ensuring the products fit into modern interior decors. By applying the same rigorous safety standards used for baby products to general home furniture—such as non-toxic finishes and tip-over restraints—AUTORU offers a distinct value proposition: furniture that is safe for the whole family.

Autoru is an OEM for baby products

In the competitive world of juvenile products, brands often face a critical decision: build their own costly factories or partner with an experienced Original Equipment Manufacturer (OEM). Based on my 20 years of analyzing supply chain shifts, AUTORU’s role as an OEM for baby products positions it as a vital strategic partner for global brands.

OEM services at AUTORU go far beyond simple assembly. They offer a comprehensive “concept-to-carton” solution that addresses the specific pain points of modern retail brands:

- Cost-Effective Scalability: Building a manufacturing facility requires millions of dollars in capital expenditure (CAPEX). By utilizing AUTORU as an OEM, brands can leverage existing infrastructure. AUTORU’s facility is equipped to handle fluctuating order volumes, allowing brands to scale up production during peak seasons (like pre-holiday rushes) without carrying overhead costs during slower periods.

- Advanced Research and Development (R&D): One of the standout features of AUTORU is its in-house R&D team. Many “manufacturers” are merely factories that follow instructions. AUTORU acts as a consultant. If a client brings a sketch of a new automatic cradle, the R&D team assesses its mechanical feasibility, suggests material improvements for cost reduction, and optimizes the design for shipping efficiency. This collaborative engineering is rare and highly valuable.

- Customization and White-Labeling: Different markets have different aesthetic preferences. A stroller color popular in Europe might not sell in Southeast Asia. AUTORU’s OEM services allow for deep customization—from the color of the powder coating on metal frames to the specific weave of the fabric on a bouncer. They provide white-label solutions where the product is manufactured to AUTORU’s high standards but branded entirely with the client’s logo, packaging, and manual, ensuring seamless brand identity.

- Speed to Market: In the baby industry, trends move fast. A new safety feature or design trend can emerge overnight. Because AUTORU controls the entire production chain—metal, wood, plastic, and electronics—they can prototype and pivot much faster than manufacturers who rely on sub-contractors for components. This agility helps client brands launch new products ahead of their competitors.

AUTORU factory certifications

In the baby product niche, certifications are not just badges of honor; they are the license to operate. A single safety recall can bankrupt a baby brand. Therefore, the transparency of the AUTORU Factory Certifications is perhaps the most critical section for any potential B2B buyer.

AUTORU operates under a strict Quality Management System (QMS), adhering to international standards that ensure consistency and safety.

- ISO 9001 Compliance: The factory operates according to ISO 9001 principles. This is the global standard for quality management. It means that every process at AUTORU—from how raw steel is inspected upon arrival to how the final box is taped—is documented, repeatable, and constantly improved. For a buyer, this guarantees that the 1,000th unit produced is identical in quality to the first prototype.

- Product Safety Standards (ASTM & EN): AUTORU engineers its products to meet the rigorous demands of the two major global markets:

- ASTM (American Society for Testing and Materials): Essential for the US market. This includes testing for lead content, sharp edges, small parts (choking hazards), and structural integrity.

- EN (European Norms): Essential for the EU market. These standards are notoriously strict regarding chemical composition and mechanical stability.

- By adhering to these standards, AUTORU ensures that their OEM clients can pass third-party lab testing (like SGS or TÜV) with ease, facilitating smooth customs clearance and retail entry.

- Social Compliance and Ethics: Modern consumers care about how products are made. AUTORU is committed to ethical manufacturing practices. This includes fair labor standards and safe working conditions. In my experience, Western brands are increasingly auditing their suppliers for social compliance; AUTORU’s transparent operations make them a “safe” partner for brands prioritizing Corporate Social Responsibility (CSR).

AUTORU Vietnam’s leading manufacturer of baby products

As we conclude this extensive overview, it is clear why AUTORU is recognized as Vietnam’s leading manufacturer of baby products. The global supply chain is currently undergoing a massive shift known as “China Plus One,” where companies look to diversify manufacturing hubs. Vietnam has emerged as the top contender, and AUTORU is the flagship representative of this industrial maturity.

Why does AUTORU lead the market?

- Integration of Technology and Craftsmanship: They have successfully bridged the gap between traditional Vietnamese craftsmanship (seen in their wooden furniture) and modern automation (seen in their robotic welding arms and automatic cradle motors). This hybrid approach results in products that feel premium yet are produced efficiently.

- Strategic Location and Logistics: Located in Vietnam, AUTORU benefits from excellent proximity to major international shipping ports. This logistical advantage translates to lower freight costs and faster shipping times to North America and Europe compared to land-locked competitors. Furthermore, Vietnam’s favorable trade agreements with many nations reduce tariff burdens for international buyers.

- Unwavering Commitment to Safety: Over the last 20 years, I have seen many manufacturers cut corners to save pennies. AUTORU’s leadership has consistently chosen the harder path of rigorous testing and high-quality material sourcing. They understand that in the baby industry, trust is the only currency that matters.

In summary, for retailers, distributors, and brands seeking a manufacturing partner that combines engineering precision, certified safety, and ethical production, AUTORU stands as the premier choice in the region. They are not just building products; they are engineering the peace of mind that every parent seeks.